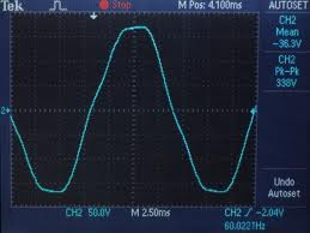

Each Winco engine driven generator set has a range of frequency regulation. Frequency is measured in Hertz (Hz). In conventional generators it is controlled by the speed (RPM) of the engine. For 60 hz applications the engine operates at 1800 or 3600 RPM depending upon the type of generator end used. It is important that the engine speed is maintained at a constant level. The engine governor maintains the engine speed.

Engine are either mechanically or electronically governed. The following animations help illustrate the differences.

MECHANICAL GOVERNOR

The mechanical governor works with weights that are connected to the flywheel. As the flywheel spins faster it will close the throttle causing the engine speed to adjust. If the flywheel speed (RPM) slows down, the weights come closer to the shaft causing the throttle to open.

ELECTRONIC GOVERNOR

The electronic governor have a mag pickup that monitors the speed of the flywheel by registering an electrical signal when raised teeth pass close by it. The mag pick up signal is sent to the electronic throttle control which opens or closes the throttle to adjust the engine speed.

Which type of frequency regulation is better? It really depends on what you need. Check out our clean power article to learn more.